T- T- T-CR20 Turbocharger Rotor Assembly For Marine Engine Parts

T- / T- T-CR series marine turbocharger's design features:

T- T-CR20 Turbocharger Rotor Assembly belongs to the part for T- / T- T-CR series supercharger, which is a radial-flow turbocharger which consists of single-stage radial-flow turbine and centrifugal compressor. T- T-CR turbochargers adopts inboard plain bearing, uncooled casings and lubricated by the engine's lube oil system.

- Max. of the compressor pressure ratio about 4.5;

- Suitable for a wide variety of fuels:heavy fuel, diesel oil, biofuel and gas

- Simple and durable design;

- Easy maintenance;

- Long service life;

- widely used in ship building, locomotive, land power station and petroleum drilling industries.

Applications:

T- T-CR series turbocharger is widely used in ship building, locomotive, land power station and petroleum drilling industries, extensively applicable to in-land and coastal transportation and fishing due to its high efficiency, small size, light weight, favorable maintainability and serviceability, adequate supply of spare parts.

T- T-CR series turbocharger includes:

| T- |

T- T-CR Series |

| T- T-CR12/S |

| T- T-CR14/S |

| T- T-CR15/R |

| T- T-CR17/S |

| T- T-CR20 |

| T- T-CR20/R |

| T- T-CR20/S |

| T- T-CR24/R |

| T- T-CR24/S |

| T- T-CR26/R |

| T- T-CR29/S |

| T- T-CR34/R |

| T- T-CR34/S |

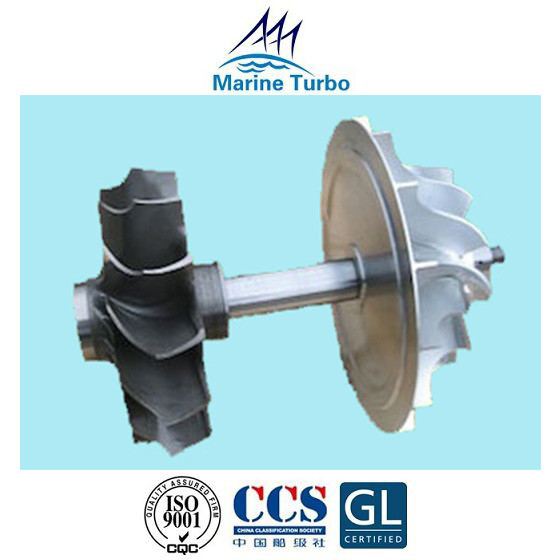

T- / T- T-CR20 Turbocharger Rotor Assembly Picture:

The composing of turbocharger rotor assembly / rotor complete:

The turbocharger rotor assembly / rotor complete consists of compressor impeller, blade shaf/turbine shaft/rotor shaft and partition wall complete.

The compressor impeller is of aluminium alloy or the more expensive titanium. ufactured from a single casting it is located on the rotor shaft by splines. Aluminium impellers have a limited life, due to creep, which is dictated by the final air temperature. Often the temperature of air leaving the impeller can be as high as 200°C. The life of the impeller under these circumstances may be limited to about 70000 hours. To extend the life, air temperatures must be reduced. One way of achieving this is to draw the air from outside where the ambient air temperature is below that of the engine room. Efficient filtration and separation to remove water droplets is essential and the impeller will have to be coated to prevent corrosion accelerated by the possible presence of salt water.

The turbocharger rotor shaft is equipped with components such as a compressor and a turbine impeller, and has a complicated structure and a large weight. If the ship is parked for a long time, the turbocharger rotor will be bent and deformed due to the long-term non-operating self-weight, which will break the matching gap between the rotor and the casing, the gas seal and the casing, and the rotor will be lost. In severe cases, the rotor is difficult to rotate and the friction is severe. A large centrifugal force is generated during operation to cause the supercharger to vibrate.

Therefore, if the ship is suspended for a long time, attention should be paid to the agement of the supercharger to prevent deformation of the rotor.

After a period of operation, the turbocharger is deformed or broken due to severe carbon deposits on the turbine blades; the compressor impeller, blade deformation or damage will change the rotor mass distribution, changing the original center of gravity of the rotor and destroying the original dynamic balance accuracy of the rotor produces severe vibration and the work is not stable.

So doing the rotor dynamic balance test is very important when the replacement parts is about to dispatch to the end user. The balance accuracy of the rotor is detected on a dedicated dynamic balance tester, repaired according to the magnitude and position of the measured unbalanced mass, and the unbalanced mass is removed and tested again until the required balance accuracy is achieved. Of course, when doing rotor dynamic balance inspection, the rotor should be in good condition, that is, there is no scratch, deformation and wear.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!